Proximate analysis: Crude protein

|

Principle and Scope |

|

|

Estimated by a process developed by a Danish chemist/brewer,

Johan Kjeldahl. He discovered that "all protein" contains about the same amount

of nitrogen (16%). He analyzed for nitrogen, which is relatively easy, and

calculated crude protein on the basis: 100/16 = 6.25, therefore: NITROGEN x

6.25 = CRUDE PROTEIN

In the presence of sulfuric acid, sodium sulphate and

a catalyst, the amino nitrogen of many organic materials is converted to

ammonium sulphate. The ammonia is distilled from an alkaline medium and

absorbed in standardized mineral acid. The ammonia is determined by back

titration with a standardized mineral base.

This method is applicable to

fish, fish products, and fish by-products. Certain species of fish such as

dogfish contain non-protein nitrogen; therefore, when analysing these species

use AOAC procedure 7.024 (12th Edition) for non-protein nitrogen to correct the

results.

|

Sample preparation |

|

|

- Sample preparation should take into account the type of

product and how it is used and prepared by the consumer:

- for fish and fish products that contain no free

liquid: comminute the sample until homogeneous.

- for products that are packed in water, brine or

similar medium that is normally discarded by the consumer: open the package

and drain the product on an appropriate size sieve for 1 to 1½ minutes.

Comminute the part of the sample retained by the screen until a homogeneous

blend is obtained.

- for products that are packed in a medium that may be

or is normally used by the consumer, e.g., fish canned in its own juice or

oil: transfer the entire contents of the package into a homogenizer and blend

for one minute or until a homogeneous mix is obtained.

- for fish meal: grind the sample in a mill or other

suitable apparatus until it will pass through a no. 20 sieve.

- Collect the homogenized sample into a thoroughly cleaned,

sealable plastic cup or glass bottle.

- Store the sample in a refrigerator or freezer until required.

- Ensure that the prepared sample is still homogeneous prior to

weighing. If liquid separates from the sample, thoroughly reblend before use.

|

Reagents |

|

|

- Sulfuric acid (H2SO4), nitrogen-free.

- Cupric Sulphate (CuSO4), nitrogen-free, anhydrous.

- Sodium Sulphate (Na2SO4), nitrogen-free, anhydrous.

- Sodium Hydroxide (NaOH).

- NaOH solution (50% w/v).

- NaOH standard solution (0.1 or 0.2 N).

- Boiling granules, selenized. Hengar granules are suitable.

- Hydrochloric acid (HCl).

- HCl standard solution (0.1 N). Standardize against 0.1 or 0.2

N NaOH standard solution.

- Conway indicator.

- Stock solution. Mix 200 mL of 0.1% Methyl Red solution

(in 50% ethanol) with 50 mL of 0.1% Methylene Blue solution (in 50% ethanol).

- Working solution. Dilute 1 volume of stock with 1 volume

of absolute ethanol and 2 volumes of distilled water. (pH change 5.4: Acid -

Purple, Alakline - Green).

|

Procedure |

|

|

- Accurately weigh a suitable quantity of fine-grained material

(ca 1.2 g for fishmeal, ca 2.5 g for solubles or homogenized fish) and place in

digestion flask.

- Add sequentially 15 g Na2SO4, 1 g CuSO4, one or two selenized

boiling granules and 25 mL of conc H2SO4 to the flask.

- Digest until solution is almost colourless or light green (2

hrs for inorganic material) and then at least a further 30 minutes. Do not heat

any part of the Kjeldahl flask above the level of the digestion mixture.

- Cool (do not allow to solidify), and cautiously add 200 mL

water. Add additional boiling granules (if necessary) to prevent bumping.

- Pipette 100 mL 0.1 N HCl into a 500 mL erlenmeyer flask, add

1 mL Conway's indicator and place the flask under the condenser ensuring that

the condenser tip is immersed in the acid solution. (volume of standardized HCl

used in distillation may be varied according to the expected nitrogen content

of the sample).

- Tilt the Kjeldahl flask containing the digested sample and

add 100 mL of 50% NaOH solution slowly down the side of the Kjeldahl flask so

that it forms a layer underneath the digestion mixture.Immediately connect the

flask to the distilling bulb of the distillation apparatus. Rotate flask to

thoroughly mix contents.

- Heat until all ammonia has passed over into the standard

acid. Collect approximately 150 mL. Caution, flask will bump. Remove

immediately (prolonged boiling and too rapid distillation of acid during

digestion should be avoided as loss of ammonia may occur).

- Wash tip of condenser and titrate excess standard HCl in

distillate with NaOH standard solution (detailed titration procedure) .

|

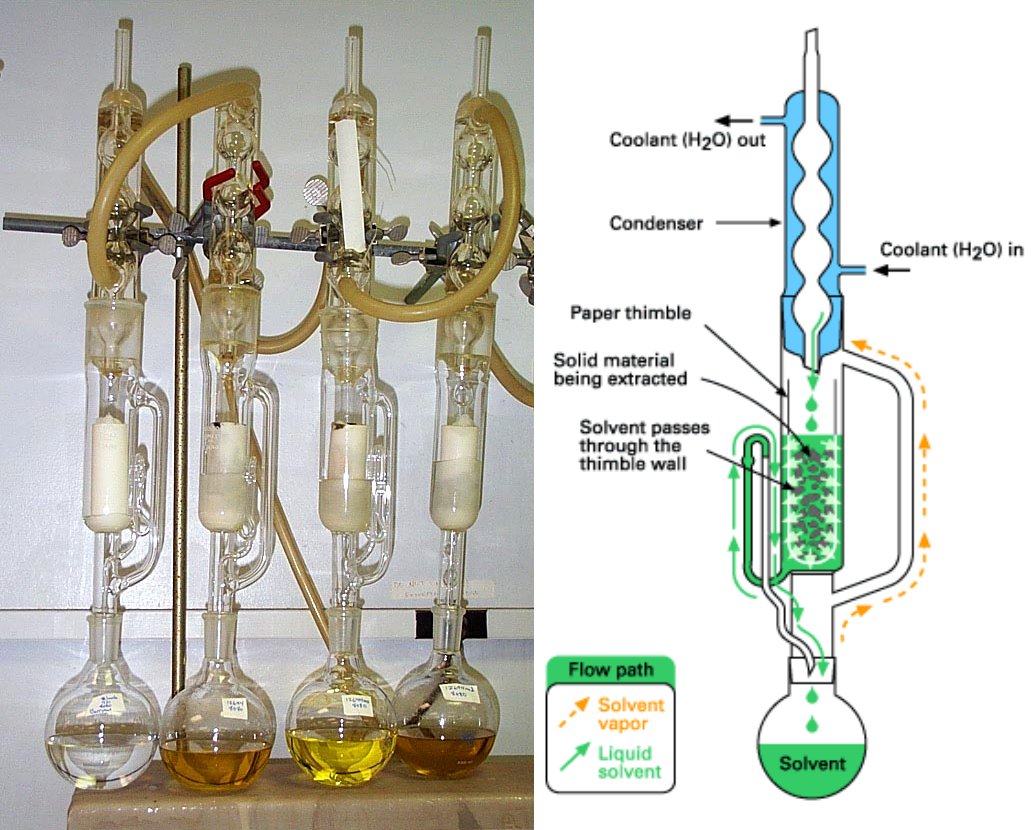

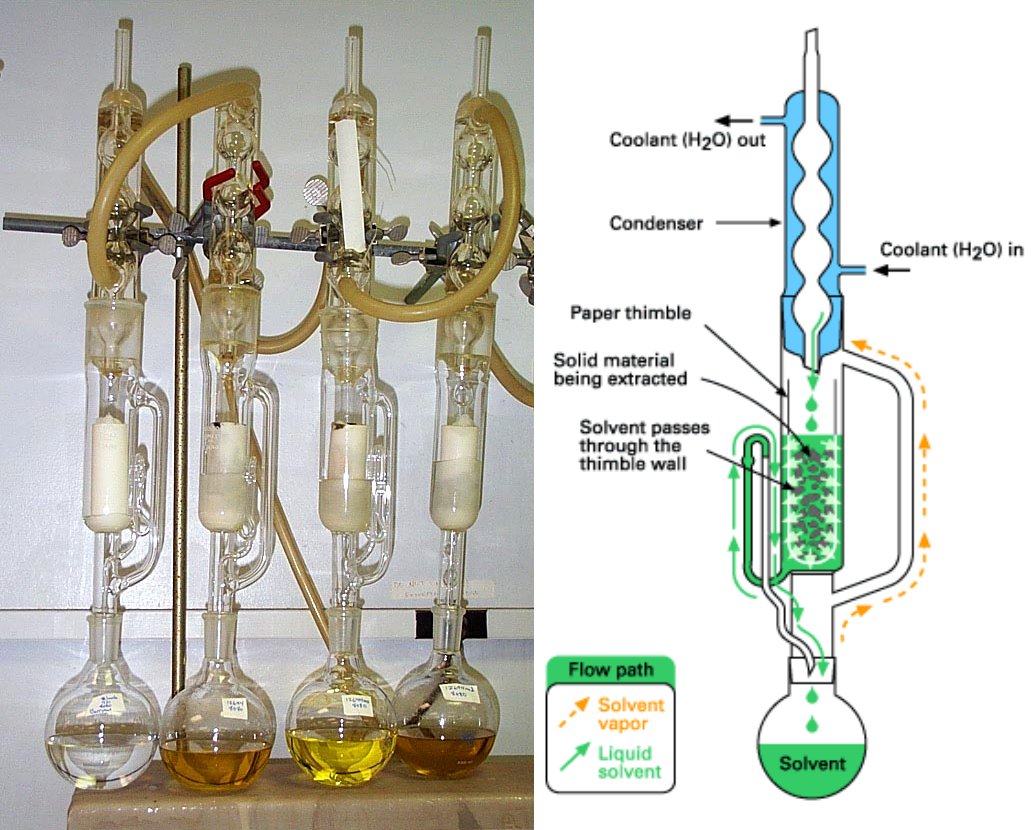

| Figure: Soxhlet apparatus and diagram |

Provide adequate ventilation for the removal of fumes during

digestion.

|

Calculation |

|

|

Calculate the percentage nitrogen (wet weight basis) as follows:

|

(A - B) x 1.4007 |

|

| % Nitrogen (wet) = |

|

x 100 |

|

weight (g) of sample |

|

where:

- A = vol. (mL) std. HCl x normality of std. HCl

- B = vol. (mL) std. NaOH x normality of std. NaOH

Calculate nitrogen content on dry basis (when moisture content

is known) as follows:

|

% Nitrogen (wet) |

|

| % Nitrogen (dry)= |

|

x 100 |

|

(100 - % moisture) |

|

Calculate the percentage protein (wet or dry basis) as follows:

- % PROTEIN = % nitrogen x 6.25

where 6.25 is the protein-nitrogen conversion factor for fish

and fish by-products.

|

Possible errors &

disadvantages |

|

|

- This procedure assumes ALL nitrogen present in the sample are

in PROTEIN form. This assumption is NOT necessarily true. Nitrogen could be in

nucleic acid (RNA, DNA), urea...

- Different proteins need different correction factors because

they have different amino acid sequences

- The use of concentrated sulfuric acid at high temperatures

poses a considerable hazard, as does the use of some of the possible catalysts

- The technique is time consuming to carry-out.

|